-Living Color

Brazil, Buenas!

I've been parsing the percentages here at D6C Mission Control, dissecting the demographics, noodling on the numbers, always looking to get more people to Talk the Dock! and have discovered some cool stats:

A significant percentage of readers are from outside of North America- UK, Australia, Holland, Brazil, Russia, Romania, Nigeria...

Okay, some of the hits might be actual readers, not searchbots.

Yeah, I might actually find a way to make some money from this gig, too.

Diddling the data, I realized that it's entirely possible that some of the rituals and requirements of Great Lakes sailing are completely foreign and incomprehensible to many from outside of North America.

Like the spring sweat-equity extravaganza known as "splashing."

I figure a little background info might help. Locals, feel free to skip to the good stuff.

Okay, if you can't find any good stuff, just skip to the average stuff.

Shut up, smartass. Just scroll down to the part that says "SKIP TO HERE"

Background:

This is four-season country. Here on the South Coast of Ontario, Canada, it gets cold in the winter, warm in the summer, and rains in between. The water often freezes all winter, and the marinas, by and large, are not equipped to allow boats to stay in the water year-round. So every fall boatyards are busy hauling boats out and storing them on the hard, then each spring the process is reversed, and the boats get relaunched, or "splashed."

As spring is a time of renewal in the natural world, so it is in a boat owner's world as well. The weeks, days, and hours of spring prior to a boat's splash are filled with scraping and sanding and painting and patching and fixing and varnishing and swearing and yelling and drinking. The "Northern Nautical" version of the 80/20 Rule becomes the practice in boatyards far and wide: 80% of the maintenance a boat will receive all year is accomplished in the 20 days prior to her being splashed.

Then you do it all over again next year.

It's worth it.

SKIP TO HERE

In splash seasons past, we have painted the deck, painted the topsides, stripped the bottom, rebuilt the top end of the engine, installed electronics, refitted the galley and cabin, varnished our asses off and generally made improvements and revisions that were cosmetic or convenience related, not critical to operation.

This season was different.

Climbing aboard to compile this season's punchlist of projects that we couldn't afford to do but couldn't afford to ignore, I checked the steering gear, and found ...

... blocks that were in bad shape.

Okay, looks like steering R&R just moved to the #1 position on the "To-do" list.

Upon further inspection, it looks like the blocks themselves are in decent shape- it's the wood under them (the block blocks?) and the mounting hardware that is shot.

So, the usual drill ensues-

1. Measure

2. Remeasure

3. Cut scrap wood (for new block block blanks)

4. Trim and shape

5. Sand

6. Cover in Epoxy

7. Sand

8. Varnish

9. Test Fit.

10. Utter Profanities

11. Re-remeasure. For Sure. This Time.

12. Repeat steps 3-9.

13. Install

Ahhh, step 13- that is always where it falls apart.

To bolt on the new block blocks I have to UNbolt the remnants of the old block blocks, and the operative word here is bolt, which implies a nut, of which none can be seen in the pictures above and you know WHY?

Because they are hidden down HERE, that's why!!

Oh, you can't see the nuts in question? That's because they are waaaaayyyy back there- behind the engine, and above the fuel tank:..

...About 5" out of reach from the quarter berth, and I am about 4" too fat to slither in there.

(Yes, Astute, Critical, ABYC-versed Reader, all of the hoses leading to/from the tank and the cockpit drain hoses should be double-clamped. More on that in a minute.)

So, obviously I need to make another large hole in my boat.

My new Matrix drill/driver/saw earns it's keep:

Drill a hole, snap off the drill head and install the jigsaw head, turn a small hole into a bigger hole, snap in a cover plate...

Snap the drill head back on, drill some smaller holes, swap out the drill bit for a Phillips head bit and drive some screws.

Last time I had to drill a big hole in my boat and install a deck plate it took 40 minutes.

This time it took less than 10.

Now I can reach the nuts AND the hose clamps.

With the old block blocks removed and the well cleaned up, I threw some paint at it, installed new blocks and put it all back together:

Clean up the displaced caulk and the paint slop and she's as good as new.

Not a moment too soon:

When I inspected the blocks last season, I figured they would last until the end of the season. They did...barely.

That wasn't the only Whiskeyjack wood that had seen better days. The swim ladder treads could no longer be tread upon.

I figured I'd repurpose Whiskeyjack's old galley locker doors into new treads.

Splintery mahogany wouldn't be an ideal choice if the treads were to be left bare, but since they are going to be finished bright, I wasn't worried about slivers.

Turns out I didn't have to worry anyway.

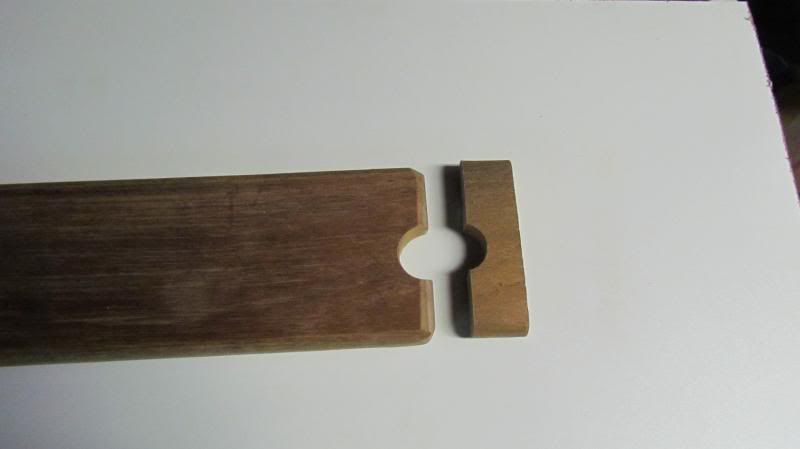

I lit up the table saw and made the first cut and discovered...

The doors weren't solid wood.

Without missing a beat, I immediately resort to Plan B, and in hindsight, a Better Plan: Cut up a couple of the companionway boards from DonorBoat.

(Y'know, you'd figure that if I am able to seamlessly adapt to Plan B when Plan A gets in the weeds thanks to years of failed Plan As, I'd have learned to just turn my Plan Bs into my Plan As.

Hasn't happened yet.

Likely won't. )

A couple of trips along the router table...

Chuck a spade bit in the Matrix, measure the spacing, drill each tread, cut to fit the swim ladder rungs, shape...

Varnish, and install.

Here's the deal: Preparing the boat for spring splash starts immediately after the boat is hauled out for the winter. But the early stage, say, oh, October through March, is devoted largely to planning and procrastination. Once the snow melts off the deck, effort is expended on exploratory sanding and scuffing of brightwork and hull.

Weather is both a factor and a convenient excuse- if it is too cold or too wet to paint or sand or varnish, one can rationalize taking a day off.

Upon setting the splash date with the yard, however, the clock starts ticking rather loudly, and excuses are no longer an option. Nothing less than an ark-construction-inspiring deluge, or surprise snowstorm will interrupt the -every-spare-moment pace of splash prep, culminating in a late night/ early morning frenzy of effort that doesn't end until Whiskeyjack is in the slings.

And each year, as I watch Whiskeyjack settle into the water, I promise myself that next year, I'll be more organized, better prepared, and procrastinate less.

Yeah, right.

And then, it's done.

And it's all worth it.

"Talk the Dock!"

Ah the joys of the old boat. I am in the process of determining what is missing from my new old boat. The one that I had on a lend lease program had just about everything. This boat while clean and uncomplicated is also "unstocked". I appreciate that when working on old boats being willing to look at things from a new angle is probably what's most most important. I appreciate your creativity and I appreciate replacing those steering blocks. Thank goodness they didn't quit on us last fall when we were out in the heavy waves that evening and trying to get back. Good old boat. She looked after us.

ReplyDeleteGavin,

Delete"Clean" is right! Your new boat looks great! Let me know what you need to fit her out- if I don't have it, Jack might, and if Jack doesn't Hilary might.

Yeah I was thinking about that great night sail when I was pulling those old punky blocks out. You're right- Whiskeyjack always looks after us- she's not fast, she's not pretty, but she is reliable.

Great posting. I have one of those access ports waiting to be installed so I can access the nuts holding my port winch and cleat. I need to expand my set of tools first beyond drill, multi-tool, sander and hammer.

ReplyDeleteBTW, I took your advice and used Home Hardware Spar varnish on my teak grab rails. They have turned out very nice. Once I complete all of the woodwork onboard (this weekend?) I will post some more pics on Sailnet in the <$100 thread. I am in the water and I want to stop working on the boat and get sailing!

Hi there,

ReplyDeleteGlad to hear you like the varnish! I look forward to seeing pics.